Product Lifecycle Management with Plone

Plone is a feature rich content management system out-of-the-box, but it can also be customized to power any content heavy, workflow driven process - in this example, multilingual paint product information

Plone at PNZ Produkte GmbH

PNZ Produkte GmbH is a niche manufactory of oil-based paints and coatings made from renewable resources. Next to its company brand product line, a substantial amount of business is generated from private label (PL) sales. These PL products are offered as a turn-key service: including promotional material, product information sheets and packaging. For some private label customers, PNZ also takes care of fulfillment to end consumers.

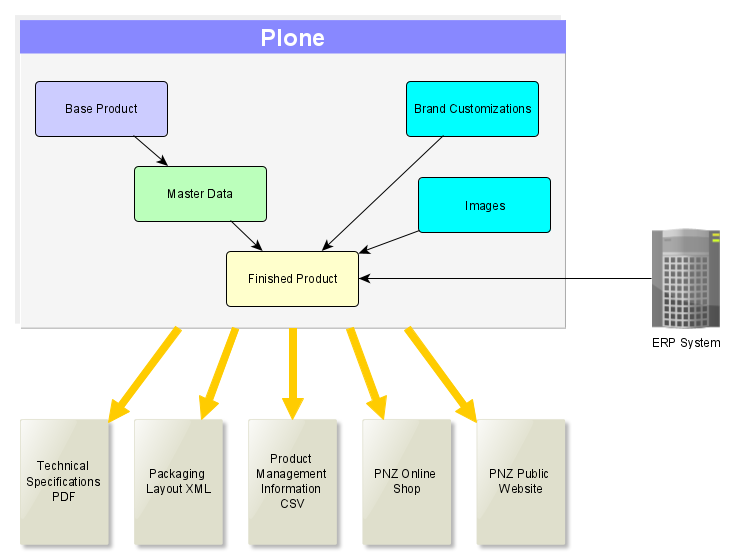

A typical finished product is derived from:

- A Base Recipe which determines the ingredients, production methods, usage safety indications and applicable mandated regulations (e.g. GHS)

- A Master Product which defines the application specifications, usage instructions, packaging sizes, pigments and other general use attributes

- A Finished Product which includes branding characteristics, marketing descriptions, article EANs and other customizations

Since 2015, Plone has been used as the engine for creating and maintaining product specifications. About 20 employees in multiple departments interact regularly with the software. The project received a “Digitalbonus” innovation award from Germany's Landesamt Oberbayern.

A Typical Product Lifecycle

When a new product is formulated, has passed its application and safety testing phase, and is ready to go in production, its specifications will be split in three separate information layers. Custom content types in Plone connect these layers and manage their contents. Plone's ability to quickly prototype content types through-the-web makes it easy to design an initial structure and refine it based on user experiences. Each information layer consists of 30 to 50 individual fields and can be extended as needs change over time. Connecting different types of data from dynamic and external sources is relatively simple as Plone offers a large variety of edit/display widgets out of the box.

At each hierarchical level, new content undergoes a quality and regulations compliance control check before going through the Plone publishing workflow. This makes the document available for use in lower layers. Any base recipe can potentially power several master products, which in turn results in a large number of finished products. The current system powers some 25,000 individual articles or SKU's.

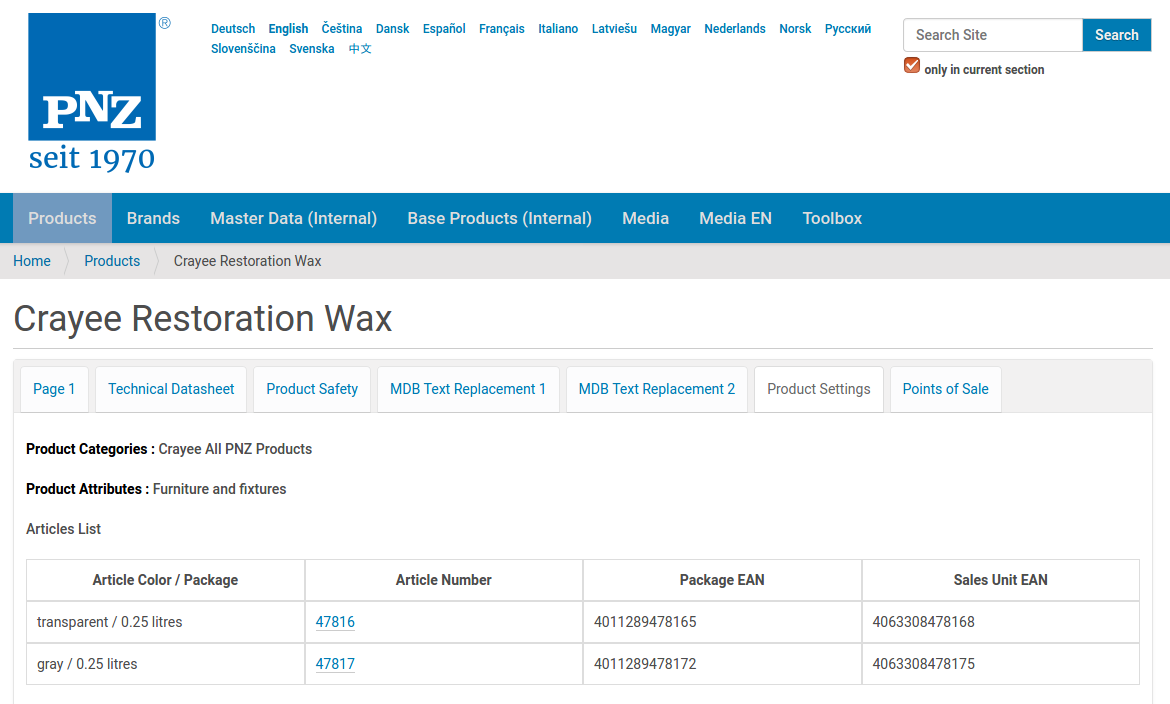

At the lowest level, a "Finished Product" content type includes product-specific overrides and any information not inherited from the recipe and master product layers.

Since products may be offered to multiple geographical markets, all information must be translated. Plone's built-in multilingual capabilities make it possible to have each individual document available in several languages. Fifteen languages are currently in use within the PNZ system. Each field in a content type can be designated as translatable or multilingual, so that updates of multilingual fields can automatically propagate throughout the various translations.

Automating Content Creation

The information contained in its product lifecycle management system allows PNZ to automate the generation of a variety of ready to use content. Plone provides the BrowserView mechanism, used in conjunction with Zope Page Templates (ZPT), to determine what should be included in the content and how it should be rendered.

PNZ creates colortone samplers and product information sheets, with a customized layout for each brand, using the tools provided by Plone. The documents then undergo a final conversion to PDF using “Produce & Publish” software, created by longtime Zope/Plone community contributor Andreas Jung at Zopyx.

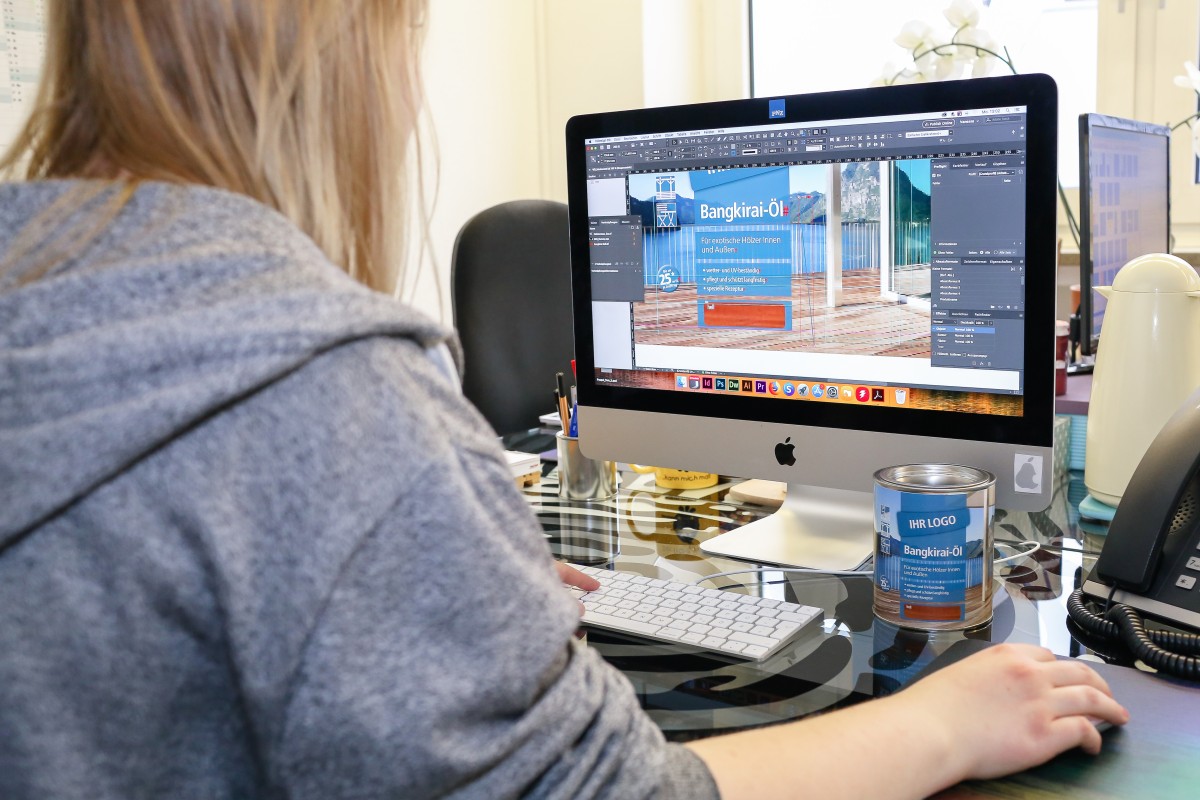

In the packaging process, Plone powers the creative design of all product labels. A BrowserView is used to draw data from multiple content types and the company’s ERP system. This will generate a set of XML files for each product and its SKU variants, plus related dynamic images such as EAN codes, colortones, certifications and GHS warning signs.

The XML files and images are then read into Adobe InDesign templates by the company's creative designers, resulting in a professionally designed wrapper for each SKU that always contains accurate information and complies with industry standards and specifications.

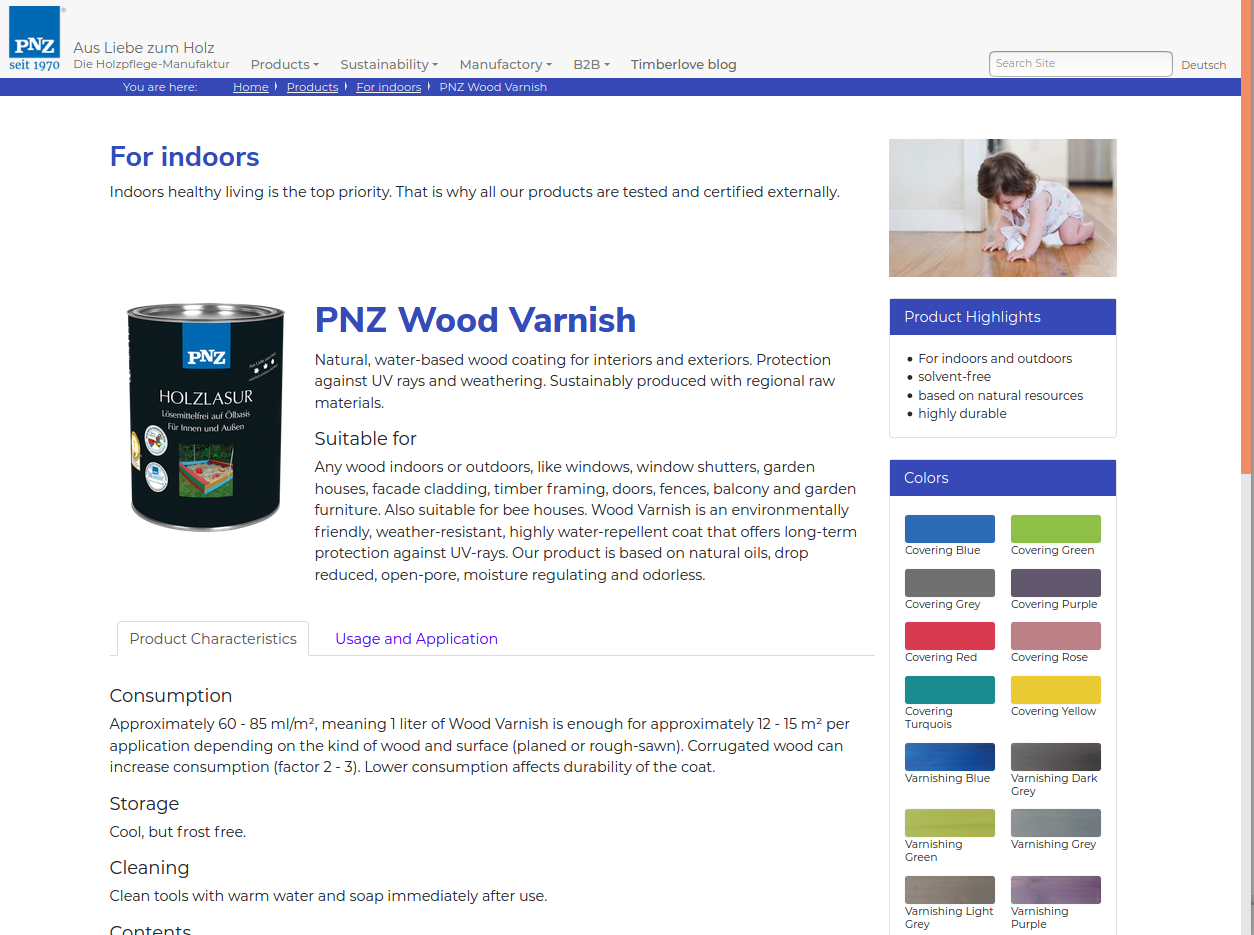

Other types of content include the generation of raw HTML and images for use in a PlentyMarkets shop, and the creation of Product Information Management (PIM) CSV export files for large customers such as DIY store chains. Finally, using plone.restapi, the system powers the product catalog of PNZ's soon to be relaunched public facing website which of course also uses Plone!